3D printing is the process of making an object out of some material, often plastic. 2D printing, or just simply, printing, is the process of putting an image on paper. They appear to be two different processes. Internally, however, the technical workings behind both types of printing have some strong similarities.

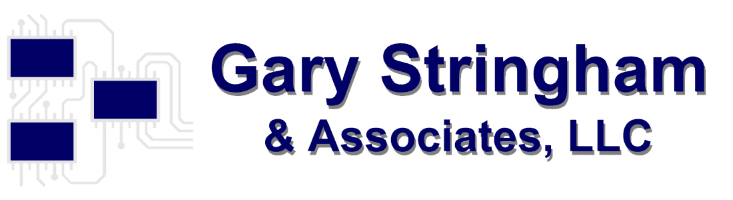

Let’s first examine 2D printing. Suppose I get on my computer and create a notched triangle as shown in Figure 1. When I send that to the (2D) printer, the printer internally must slice it up. The ink head or laser beam scans back and forth across the page (commonly referred to as the X direction) as the page slowly moves forward (commonly referred to as the Y direction.) The paper only moves forward, never back. The image has to be sliced so that on one X-direction pass, all locations along that line/row will be printed as needed. This slicing is illustrated in Figure 2. The top slice is printed on one pass, the second slice on the next pass, and so on. When all those slices are printed, the result is the desired image

I’m simplifying things here as the slices are not as thick as in the drawing, but much thinner which makes the diagonal sides appear smooth.

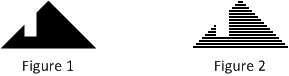

Old pen plotters had the ability to, not just go side to side (X direction), but to also go forward and backwards (Y direction) on the paper. Figure 3 illustrates how the pen moves up, down, sidewards, and even diagonally as needed to draw the outline of the notched triangle, and then back and forth to fill in the triangle.

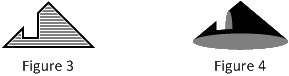

Now suppose that the 2D drawing in Figure 1 is a side view of a 3D object, a cone with a notch, as illustrated in Figure 4. When that 3D drawing is sent to the 3D printer, it too must be sliced up. Figure 5 shows all the slices as layers. The bottom layer is printed first on the printer’s tray. The tray then moves down or the print head moves up (Z direction) and the next layer is printed. Each layer is different creating the shape as it gradually builds up.

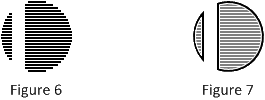

Not only is there slicing in the Z direction, but there is also slicing in the Y direction, as illustrated by Figure 6, which shows the fifth layer from the bottom. Some 3D printers can move freely in any X and Y direction so it might traverse the layer like in Figure 7, drawing the outside first then filling it in.

Other similarities exist between 2D and 3D printing:

- Both use microcontrollers to interact with the host computer, the moving mechanical parts, and the print media.

- Both have motors to move the paper and ink head, or the tray and extruder.

- Both sense when motors have moved mechanical parts to their limits.

- Both sense the presence or absence of the printing media, whether ink, toner, or plastic.

- Both need to control and monitor the heat used to spray the ink, fuse the toner, or melt the plastic.

3D printing has been around a few decades but just recently has been developed into low-cost, desk-top models making them available for hobbyists. Just as personal printers started becoming available for the average home user many years ago, 3D printers could become prevalent for home use in a few years.

Gary Stringham is an embedded systems consultant with 15 years of experience in (2D) printing. He has also served as an expert witness on a few printer-related litigation cases. He can be contacted at 208-939-6984.